|

|

|

|

Technology LCD Displays / Passive Displays

|

|

|

|

|

| LCD cell in inactivated

state |

|

LCD cell in activated

state |

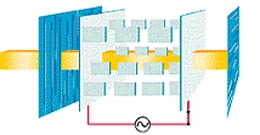

Liquid crystals have the property of changing their alignment

when an electrical voltage, resp. electrical field, is applied.

In this way, it is possible to allow light to pass, or not to

pass, through the cell.

Contrast

The contrast value is always the ratio of the brightness of

the activated, resp. inactivated pixels.

Brightness of pixels in

inactivated state

K = --------------------------------------------------------

Brightness of pixels in

activated state

The contrast is therefore always given as a ratio without a

unit, e.g. 20:1

Viewing Angle

The viewing angle is used to refer to the angle at which the

display reaches a particular contrast ratio. The reference contrast

value is specified according to the viewing angle.

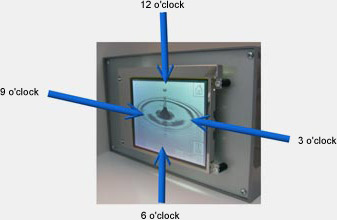

Usually four angles are given: the angles measured from the

centre to left and right, as well as the angle measured from

the centre to the top and the bottom.

|

|

Viewing Direction

The viewing direction refers to the preferred viewing angle

of an LCD display.

Particularly in the case of passive displays, the viewing angles

are not identical from all sides.

Due to the production process, there is always a larger viewing

angle on one side (always viewed from the middle of the display).

A clock-face is used to indicate this preferred side.

For example, if the viewing angle of a display is largest from

the middle to the bottom, the viewing direction will be indicated

as 6 o’clock.

By adjusting the production process, the viewing direction can

be turned in practically any direction. In this way, a display

can be adapted to the clients’ requirements.

If a display is installed in such a way that the viewer sees

it from below, then it is possible to build in a viewing direction

of 6 o’clock.

Should the display be viewed from above, a 12 o'clock display

can be fitted.

It is also possible to produce displays with a viewing direction

of 3 o'clock or 9 o'clock.

|

|

Positive und Negative Mode

A passive LCD can either be produced in positive mode or negative

mode.

Positive mode means that the activated pixels are dark and the

background is light.

Negative mode means that the activated pixels are light and

the background is dark.

With the use of software, the display can be inverted.

|

|

|

|

|

|

|

|

| Positive Mode |

|

Negative Mode |

|

Negative Mode Inverted

by software |

|

Positive Mode

Inverted by software |

Reflective / Transmissive / Transflective

The function of an LCD is based on the fact that light flows

from the back to the front of the LCD cell. In this way, light

can either come from behind (background lighting) or from the

front (surrounding light, e.g. the sun). If the light comes

from the front, it must be reflected on the back of the display.

According to the application and requirements, the display can

be assembled in three ways:

Reflective

There is a reflector behind the actual LCD cell which completely

reflects the light entering from the front. A reflective display

only works with surrounding light: the readability improving

the lighter the surrounding is (sun light).

Advantages:

Disadvantages: |

– low power

consumption (needs no background lighting)

– cannot be read in dark surroundings |

|

|

Transmissive

A transmissive display only works with the light of the background

lighting. The readability improves the darker the surrounding

is.

Advantages:

Disadvantages: |

– very good readability in dark

surroundings

– readability deteriorates with strong surrounding

light (direct sun light).

– the background lighting must always be switched

on (power consumption, life span). |

|

|

Transflective

A semi-transmitting, reflective film is mounted behind the LCD

cell. This means that the surrounding light entering from the

front can be reflected, as well as allowing the light of the

background lighting to flow to the front.

Advantages:

Disadvantages: |

– good readability in all environments

(light or dark)

– the background lighting can be switched off in

light surroundings (power saving).

– A transflective display is a compromise between

a reflective and a transmissive display.

In extreme conditions (very light or very dark surroundings),

a transflective display does not achieve the same good

results as a reflective or transmissive

display. |

|

|

Background lighting

Different background lighting can be used, depending on the

size and usage:

CCFL (Cold Cathode Fluorescent Lamp)

A CCFL tube generates a bright, white light.

To operate, an inverter is necessary, which generates an alternating-high

voltage of 400-600 V. The clock rate of the alternating voltage

typically lies between 30 to 50 kHz and usually causes considerable

EMC disturbances.

Due to the high brightness, CCFL tubes are used for larger displays.

With very large displays, several tubes can be used.

LED (Light Emitting Diode)

LEDs are used, either as a matrix to the direct lighting of an

LCD, or as LED-strips with a light conductor as background lighting.

LEDs are available in different colours (yellow-green, white,

blue, orange, red, etc) and allow a high variability (e.g. mixing

of colours, etc).

The brightness of LEDs is smaller than that of CCFL tubes, which

is why, for construction and economic considerations, LED background

lighting is only used for display sizes up to approximately

5.7’’.

EL foil

An EL foil consists of a phosphor layer which emits light when

an alternating voltage is applied. The foil is very thin, which

brings construction advantages in the design of an LCD module.

The necessary alternating voltage is generated by an inverter,

which in turn can cause EMC problems.

Different colours are available (blue, turquoise, green, yellow,

red, white, etc).

Luminova film

Luminova consists of a fluorescent layer, which still glows

for up to two hours in the darkness. Luminova film does not

require any power supply.

Life span of background lighting

The life span of an LCD is defined by the life span of the background

lighting.

The brightness of the background lighting decreases with the

operating time. The end of the life span is defined when only

50% of the original brightness remains.

Typical values for background lightings:

CCFL: 10'000 to 50'000 h

LED: white & blue: 10'000 to 20'000 h

yellow-green: 100'000 h

EL-Folie: 3'000 to 10'000 h

Application of LCD displays

General information

An LCD consists of a combination of glass and a polarizer. The

polarizers are made from a stretched synthetic film. The following

safety regulations should be kept:

- The temperature values which are indicated in the specifications

should be maintained during operation and storage. Polarizer

degeneration, the build-up of blisters, or the peeling-off

of the polarizer itself can occur with humidity, or if the

temperatures are too high.

So-called vacuoles can develop if temperatures are too low,

an irreversible damage, which affects the liquid crystals.

Particular care should be taken that no condensation builds

up on the LCD. If the storage is in a warm environment at

above 40°C, the relative humidity should lie under 60%.

While in operation, constructive measures (fans, mechanical

measures) should ensure that no condensation occurs.

- The polarizer may not be touched, pressed or rubbed with

hard objects (e.g. glass, ball-point pens, etc.).

- The LCD may not be cleaned with products containing acetone,

toluene, ethanol, or isopropyl alcohol. Hexane is recommended

for cleaning purposes.

The display can be cleaned with a soft, antistatic cloth

(e.g. cloth used to clean glasses) and possibly some petroleum

ether, if the display has dust on the surface.

Oil, fat, saliva and water should be removed from the display

as quickly as possible.

- Glass is breakable! Avoid any impacts, particularly on

the edges and corners of the display.

ESD measures

LCD modules are usually equipped with CMOS-ICs. Therefore, the

same care should be taken in handling LCD modules as with pure

CMOS components:

- When handling LCD modules, the operator must be earthed.

- Before the LCD module is taken out of the electrostatic

packaging, it is necessary to ensure that the operator and

the LCD module have the same electrical potential.

- If soldering is necessary on the LCD module, it must be

ensured that the soldering equipment is earthed.

- If the LCD needs to be screwed onto something, the screwdriver

must be earthed (especially with electrical screwdrivers).

- Working clothes and the workplace must be earthed.

- To avoid the generation of electrostatic fields, the air

in the workroom should not be too dry (a relative humidity

of 50 to 60% is recommended).

Soldering on LCD modules

If a plug, cable, or something similar needs to be soldered

onto an LCD module, the following parameters must be kept:

Soldering temperature: max. 260°C

Soldering time: max. 3 to 4 seconds

Unless a halogen-free soldering flux is used, the flux should

be removed from the LCD module after the soldering process.

The surface of the display should be safeguarded by a protective

foil or cover against soldering splashes.

Safety

Should the glass of an LCD display break, there are likely to

be sharp edges. Depending on the use, certain measures have

to be taken so that the user will not suffer injury in the incident

of glass breakage (e.g. cars).

Should the liquid crystals leak out of the display, any body

parts which have come into contact with this should be washed

with soap and water.

Liquid crystals should never be swallowed. Even though toxicity

is extremely low, the utmost care should be taken when handling

liquid crystals.

Passive LCD / Passive Displays

Passive displays contain no active electronic components between

the two glass plates (as opposed to TFT).

All the necessary components to control the LCDs are to be found

as an IC on the outside of the active surface.

TN (Twisted Nematic)

This is the simplest LCD technology. The angle of rotation of

the liquid crystal is 90°.

This technology is used for smaller displays up to a multiplex

rate of around 1/32 Duty:

these are mainly used for segment displays and in the automotive

industry.

HTN (High Twisted Nematic)

The angle of rotation of the liquid crystal is 120°. This

leads to a better viewing angle and better contrast as opposed

to TN technology. HTN has the same limitations as TN.

STN (Super Twisted Nematic)

Here, the liquid crystal has an angle of rotation of 170°

to 270°.

For displays with a larger Duty (from 1/16) better viewing angles

and contrasts can be produced.

STN displays can be manufactured with the background colours

of yellow-green, grey, or blue.

FSTN (Film STN)

An additional synthetic film (retardation film) placed on

the surface of the display ensures that the display can be seen

with either a white background and black pixels (or the other

way around). See positive and negative mode.

DSTN (Double STN)

To compensate the temperature dependence of the LCD cell,

a second LCD cell is mounted on the first. The direction of

rotation of the liquid crystal in both cells is counter rotating.

Consequently, the effects of temperature dependence are cancelled.

This technology is time-consuming and therefore expensive to

produce and is mainly applied in the car industry.

CSTN (Color STN)

An additional colour filter in the colours of red, green and blue is placed between

the glass plates. A pixel of a CSTN module consists of three

sub-pixels with the colours of red, green and blue.

Through differential controlling of the brightness of the three

sub-pixels, the human eye perceives all three sub-pixels as

a single pixel of the mixed colours.

|

|

|

|

|

|

|

Admatec AG

Fabrikstrasse 10

CH-4614 Hägendorf

Fon +41 62 896 00 48

Fax +41 62 896 25 80

info

|

|

|